Requests also accepted in Thai affiliate

Licensed Smell Examiners certified by the Japanese government will respond to your inquiry with

responsibility.

Combining the most advanced equipment allows us to handle any situation.

Inquiries: Contact form

Many Japanese manufacturers have established local affiliates and shifted their manufacturing facilities to

South East Asia.

These new factories and new worksites have invigorated the market; however associated environmental problems

cannot be ignored. We have the systems to resolve these problems.

environment.

The primary reason for Japanese companies moving manufacturing bases to South East Asia appears to be the

combination of Japanese brands and South East Asian costs. Our company has been successful in realizing this for

the environmental technologies.

For example, in cases where requests have been issued by a Thai affiliate of a Japanese company, and

environmental measures implemented, almost all of the manufacturing has been done in Thailand.

Naturally, we have provided guidance with our world-class environmental technology to Japanese quality

standards.

Our company acts as the general manager, combining Japanese technology and Thai labor in the delivery of

environmental equipment.

Future growth of the economies of South East Asia is expected to resemble that of the previous Japanese economic

boom.

As with industrial pollution during the Japanese economic boom, industry will undoubtedly be required to comply

with environmental measures in the coming economic boom in South East Asia.

If we are able to support environmental measures undertaken by Japanese manufacturers in South East Asia, this

will also allow our company to accomplish our mission of contributing to the future of global

environment.

We wish any corporation who has plans about environmental measures to contact us.

Recent Overseas Deliveries

environmental, dust, waste water treatment, and odor problems on a casting line for a manufacturer

on the casting line. We immediately assumed that the factory was in Japan. On further discussion, however,

it was discovered that the plant was in Thailand, and was the case that gave us the final push to our wishes

to expand our operations overseas.

Casting involves pouring the molten metal into molds. Manufacture of the sand molds involves the use of a

resin to solidify or bond the sand. When the when the molten metal is poured, the resin bubbles with the

heat, releasing smoke and odors.

Localized ventilator hoods were already in place on the line, however they were insufficient for the job,

and there was concern that problems would arise if the same system was employed in a new casting

line.

We proposed comprehensive measures covering the existing localized ventilation ducting and measures to deal

with odors in the exhaust gases, and after a period of six months during which our personnel visited the

site a number of times, we delivered the equipment.

Dust collection and deodorizing equipment (2,400

㎥/min)

Ducting inside the factory

Odor Control

which eliminates odors emitted from manufacturing plants and processing facilities.

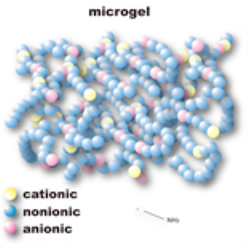

The Type-H uses a microgel deodorant method in the flushing to achieve low running costs.

The Type-HII is a high efficiency deodorizer with low running costs that uses an ozonated water spray

method.

The Type-F is a flushing scrubber that specializes in dust elimination under high temperature and high

humidity.

Contact us regarding other models available.

microgel deodorizer with small – large airflows and low – medium concentration odors. These deodorizers

spray the deodorizer into exhaust ducting to achieve major reductions in odor levels.

Since the exhaust ducting is used as the reaction chamber, the equipment is compact and light-weight,

consisting only of the deodorizer spray unit, piping, and spray nozzle, and can be used flexibly in confined

spaces.

The equipment can be installed at a cost of 1/10 to 1/3 of that of conventional combustion or activated

charcoal systems.

million) polymer compound. Its absorption effects are usable whether the odor is acidic, neutral, or

alkaline. The proportion of the reactive group in the microgel is adjusted to suit the odor component at the

customer’s installation, thus permitting maximum effect at minimum cost.

The microgel itself is odorless, and readily biodegraded by microorganisms in the environment. It can

therefore be released into the atmosphere, without the expense of additional waste water treatment

facilities.

→審査結果書はこちら(PDFが開きます。)